The choice of NC kind considerably impacts the press brake’s performance, simplicity of use, and General efficiency in sheet metal fabrication functions.

Have you ever ever wondered how a press brake shapes metal with this kind of precision? This informative article unveils the fascinating components and functions of the press brake, displaying you its vital part in production. By the tip, you’ll grasp how Just about every part contributes to its potent functionality.

Most back gauge systems include a swing-up or retractable style and design. This attribute enables the gauges to rotate upwards or retract when vital, avoiding possible collisions Along with the sheet metal in the bending system.

Copper can be a delicate material and sheets are easy to bend. On the other hand, it requires thorough handling and controlled pressure in order to avoid floor hurt or cracking. On top of that, copper’s shiny aesthetic appeal can make it popular in electrical and several other apps.

In the event you position the bends also near to each other in style, it may cause alignment problems and boost the residual stress. Thus, an acceptable length between them is vital, a minimum of three times of thickness.

These technological advancements have created press brakes increasingly eye-catching to producing organizations across a variety of sectors, from automotive and aerospace to HVAC and buyer electronics.

HYDRAULIC CYLINDERS (in hydraulic press brakes) where a piston driven by a fluid (oil) less than pressure from the pump moves the upper beam (or, rarely, the bench), generating the necessary power for bending.

The term “brake” is closely relevant to “break” and has its origins from the 15th century, the place it had been utilized to explain an instrument for crushing or pounding.

The oil seal ring is often a critical ingredient in hydraulic press brake machines, actively playing a vital position in sustaining system integrity and operational efficiency.

Their Key function is twofold: to keep up the sheet’s situation all through bending and to circumvent substance drop-off in the course of the higher beam’s return stroke. This twin functionality noticeably enhances operational security and efficiency.

Locate a nearby distributor or reseller

Engaged on a task and wish to bend and shape your metal into unique types without acquiring the mandatory machinery? Let us consider away the guess perform and get it done for you personally!

This twin-phase operation boosts both equally basic safety and accuracy during the bending operation. The pedal switch also controls get more info the retraction from the ram following the bend is total, returning the press brake to its open place.

The phrases “Brake Press” and “Press Brake” are in truth used interchangeably inside the metal fabrication marketplace, each referring to some precision machine tool designed for bending sheet metal and plate.

Edward Furlong Then & Now!

Edward Furlong Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Suri Cruise Then & Now!

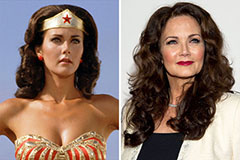

Suri Cruise Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!